Custom Hydraulic Valve Block Manufacturer Since 1980

As a professional hydraulic valve block manufacturer, xcd can also provide you with customized hydraulic valve blocks if you send us hydraulic block design pdf and 3D drawings. xcd Hydraulics is your professional hydraulic manifold manufacturer and supplier in China.

Hydraulic Valve Blocks We Made

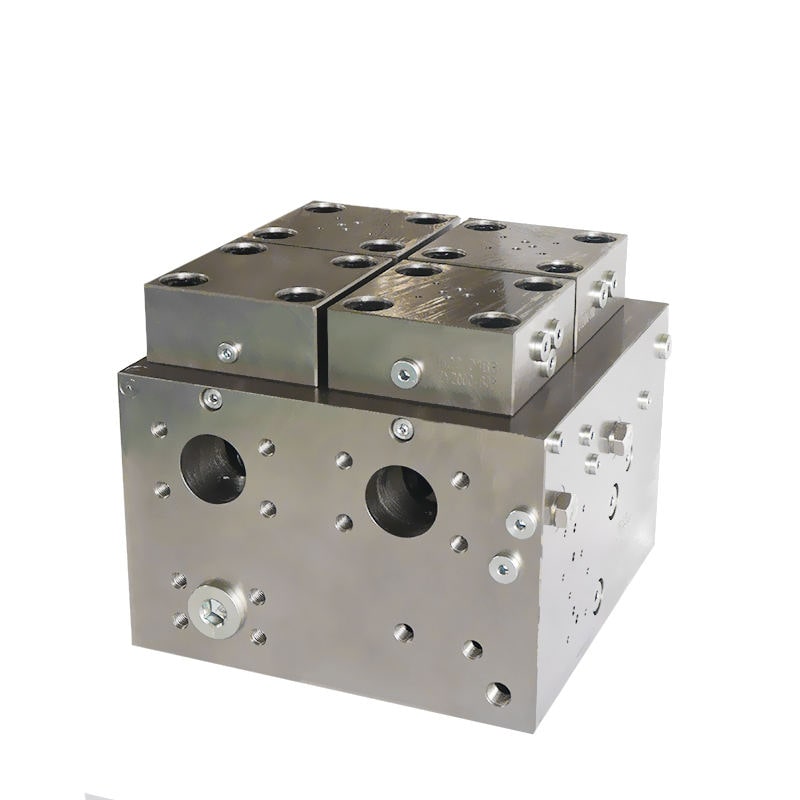

Custom Hydraulic Valve Block

Custom Hydraulic Valve Block

Custom Hydraulic Valve Block

Custom Hydraulic Valve Block

Custom Hydraulic Valve Block

Custom Hydraulic Valve Block

Reasons to Choose Our Custom Hydraulic Valve Block

| Processing | CNC Turning | φ0.5 - φ300 * 750 mm | +/-0.005mm | |||

| CNC Milling | 510 * 1020 * 500 mm(max) | +/-0.01mm | ||||

| Material Available | Stainless steel: SS201,SS301,SS303,SS304,SS316F,SS316,420,etc. | |||||

| Steel: Carbon steel, alloy steel,mild steel,4140,4340,Q235,Q345B,20#,45#,etc. | ||||||

| Aluminium: AL6061,AL6063,AL7075,AL5052,AL6082,etc. | ||||||

| Brass: HPb63,HPb62,HPb61,Hpb59-1,H59,H62,H68,H80,H90,etc. | ||||||

| Copper:C11000,C12000,C36000,etc. | ||||||

| Surface Treatment | Stainless Steel | Polishing, Passivating, Sandblasting, Laser Engraving, PVD Coating | ||||

| Steel | Zinc Plating, Nickel Plating, Chroming Plating, Black Oxide, Heat treatment | |||||

| Aluminum | Clear Anodized, Color Anodized, Sandblasting, Brushing, Polishing, Chroming | |||||

| Brass | Nickel Plating, Chroming Plating, Polishing | |||||

| Plastic | Painting, Chroming Plating, Polishing, Sandblasting, Laser Engraving | |||||

| Application | Auto parts,Motorcycle parts,electronic parts,Machinery parts, Sports goods parts,Food equipment parts,Household parts,etc | |||||

| Tolerance | +/-0.005mm | |||||

| Certification | ISO9001:2015 | |||||

| It can match ROHS, SGS and Environment protection. | ||||||

The hydraulic valve blocks help control the direction, pressure, and flow of liquid in the hydraulic valve. Using an oil block allows us to simplify the installation and design of the hydraulic system. It also facilitates the integration and standardization of the hydraulic system. The oil block is thus conducive to lowering manufacturing costs and improving reliability and accuracy.

Our experts can use the latest Solidworks 3D CAD/UG/SOILDWORKS/PRO-E to provide a custom-designed design solution to our client’s needs. The quality control team strives to ensure top-notch quality by doing inspections and valve pressure tests.

About Our Hydraulic Valve Block Processing Technology

Pretreatment

The oil roadblock material has to make sure the internal part is dense and without defects like trachoma or interlayer. We also test the blanks whenever necessary. Large steel blocks and cast iron need aging and pre-treating before processing.

Machining

For fine grinding, we carry out milling, planning, benchmarking, and planning valve blocks. The surface roughness of oil roadblocks must meet the design needs. The installation surface, especially the flange, pipe joint, and hydraulic valve, should not be defective.

Deburring

We chamfer the valve block after machining it. The entire network of the valve block, including the intersections, needs complete removal of burrs. The presence of burrs can ruin the efficiency of the entire hydraulic system.

Cleaning

Before assembly of the oil block, we thoroughly clean its parts. The cleaning liquid needs to be antirust like oil or kerosene. The cleaning happens at a specific pressure for all flow channels and blind holes. Cleaning removes dirt, iron filings, and debris.

Why Choose XCD for Hydraulic Valves Block?

✓Industry-Leading Expertise and Tools: Our team comprises seasoned engineers with a wealth of experience in designing custom hydraulic manifolds. Their expertise ensures that every manifold is meticulously crafted to match your exact specifications, guaranteeing optimal performance and efficiency.

✓Tailored Solutions: At XCD, customization is at the heart of what we do. We understand that each hydraulic system is unique, and we take the time to comprehend your specific requirements. Our tailored solutions ensure that the custom hydraulic manifold seamlessly integrates into your machinery, eliminating compatibility issues and maximizing functionality.

✓Cutting-Edge Technology: We leverage the latest advancements in hydraulic technology and manufacturing processes to create custom manifolds of unparalleled quality. By staying at the forefront of innovation, we ensure that your hydraulic systems benefit from the most advanced and efficient solutions available.

✓Rigorous Quality Control: Quality is non-negotiable at XCD. Every custom hydraulic manifold undergoes rigorous quality control checks at every stage of production. This dedication to quality guarantees that your manifold operates flawlessly even in demanding conditions, minimizing downtime and maintenance costs.

✓Prompt Delivery: Time is of the essence in the industrial world. With XCD, you can rely on the timely delivery of your custom hydraulic manifold. Our efficient production processes and commitment to meeting deadlines ensure that your machinery experiences minimal disruption and downtime.

✓Customer-Centric Approach: Our clients' satisfaction is our ultimate goal. We prioritize open communication and collaboration throughout the design and manufacturing process. Your feedback and input are valued, allowing us to create custom hydraulic manifolds that exceed your expectations and contribute to the success of your operations.

Get Your Free Hydraulic Valve Block Quote Today

Our engineering team and quotation system are always up to date. We deliver quotes in 24 hours or less, depending on the project specs. Our customer care team will contact you directly to ensure you understand all aspects of the quotation and answer any questions.